We use concrete control joint filler and concrete expansion joint filler

Concrete control joints are intended to be cut the first or second day following placement of the slab at either 25% or 33% percent depth (depending on the day cut). Their purpose is to “control” stress cracking in the slab as the concrete expands and contracts with changes in moisture and temperature. If desired, control joint filler can be installed.

Polyurea joint filler is intended to give the concrete joints protection under weight and traffic. This is a 2-part semi-rigid product that cures quickly, reaches high compressive strength, and forms a 3-sided bond.

This type of concrete joint filler can be used in new construction in control joints or in existing concrete floors where traffic is high and concrete joints need protection. When used in conjunction with polished concrete, joint filler is ground and polished smooth to provide a seamless floor that is not only protected, but easier to clean keeping debris out of the cracks.

Some control joints are filled with foam, zinc (or other metal) strips, epoxies, or are left unfilled. This type of concrete joint sealant sees the most failures resulting in cracked and broken concrete, as opposed to concrete joint filler we use, as they lack the flexibility to withstand heavy industrial traffic.

When varying types of concrete joint fillers fail, concrete floor joint repair is needed. This process differs depending on the environment. All concrete joint repair requires assessment of the load transfer weight, the strength of the concrete, and the hardness of the concrete to determine the appropriate concrete joint repair method.

The concrete expansion joint is visibly larger than the control joints and they allow for movement of the concrete slab due to vibration, settling, or temperature changes. The most common type of concrete expansion joint filler is caulk. Expansion joint caulk (or expansion joint sealant) is typically installed over backer rod or other foam insert, it forms a bond on 2 sides only.

If the expansion joint filler has cracked or broken away from one side of the joint it is considered a failure. Further, if the concrete joint filler has caused more concrete damage such as crumbling, cracking, or broken concrete at the joint, it is in need of concrete joint repair.

We can perform the necessary concrete expansion joint filling for your concrete restoration project to protect the concrete from heavy forklift traffic and load transfer.

Allen’s Polished Concrete is specialized in commercial and industrial concrete floor repair. We perform industrial concrete repair and concrete restoration where damage has occurred or needs prevention. We repair concrete cracks, concrete spalling, and joint repair such as stabilization, rebuilding, and sealing. We use the highest quality concrete products to perform aesthetic and structural mortar repairs to ensure lasting results. In addition, other concrete repair products are utilized for patching concrete and concrete crack repair where weathering and settling have damaged the concrete slab. Our concrete floor repair services are detailed below:

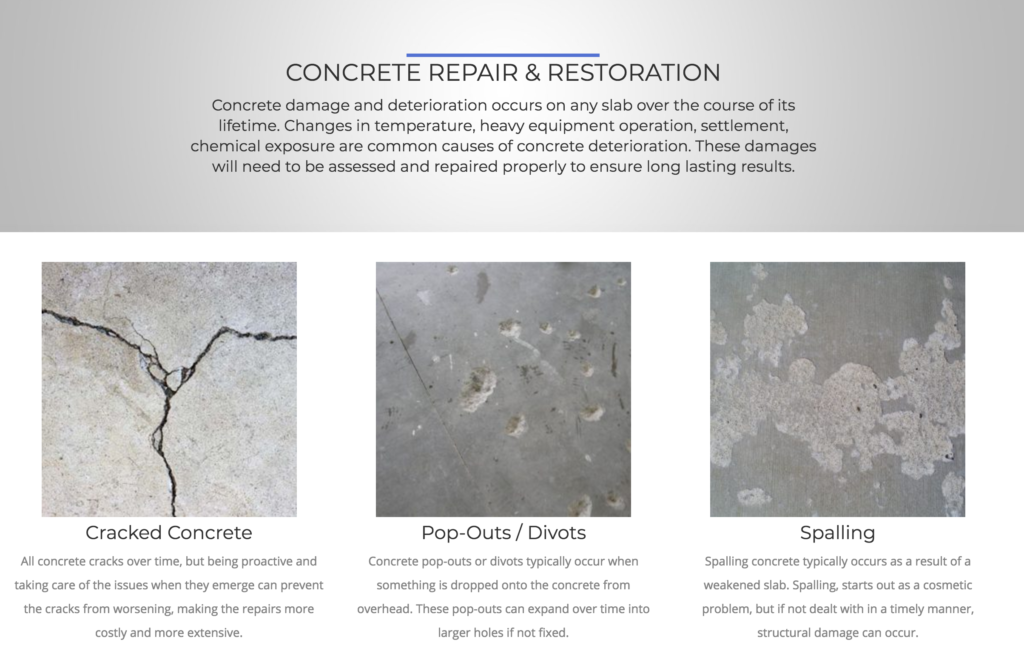

Cracked Concrete: The truth is, if your concrete hasn’t cracked yet…it will. If the cracked concrete is fresh due to settling, it might be small, but over time with forklift and foot traffic, its damage will increase and require a concrete crack filler or in some cases concrete patching. In order to fix cracked concrete, concrete crack filler can be applied depending on the size. For large concrete crack repair contact us to discuss the extent of the damaged concrete floor as sometimes these are structural cracks that may require expansion joint stabilization and repair.

Concrete Pitting or Divots: Concrete pitting is usually the result of some type of manufacturing or machine operation. It is common in automobile service bays and manufacturing plants where bolts and tools are dropped from overhead. Concrete pitting can be remedied with several different concrete repair products. If concrete pitting is not corrected it can develop into larger concrete holes overtime. Allen’s Polished Concrete is equipped with many different applications for repairing concrete holes. Holes and concrete pitting may be skim-coated with a durable treatment or cut out and patched with a thorough mortar repair. The concrete patching compound is chosen based on the appropriate needs of the customer’s needs and budget. Concrete patching can be a very useful tool to your floor to prevent injuries.

Concrete Spalling and Erosion: Concrete spalling is often unavoidable unless it is prevented at the time of pour. The concrete design mix must be adhered to (not over-watering) as to not weaken the slab. Spalling concrete is noticeable as flaking or chipped concrete at the surface. Even if you feel that these things are purely cosmetic, overtime they can cause structural issues to the foundation and weaken the slab itself. Similar to our patching of holes and concrete pitting, we have various mortar repair options as well as other durable concrete repair products suitable to address your concrete repair needs.

Damaged or Spalled Joint Repair: Concrete joint repair is a common problem seen in industrial concrete floors. Many of our customers have tried repairing this problem themselves, but they are merely putting a band aid over the problem and not addressing the root cause. When repairing concrete joints (either expansion joints or control joints and even structural concrete cracks), it is important to understand the cause of the problem and to choose the right concrete joint filler.

Joint Rebuilding: When the concrete joint damage is far too damaged ( a joint widened over 1″), it is time for a joint rebuilding concrete repair. This type of repair requires more steps than minor joint repair, but the downtime is often under 2 hours per area.